The Combination of the Carton Industry and DIY Rivets Creates a New Furniture Market

The Combination of the Carton Industry and DIY Rivets Creates a New Furniture Market

"Click! Click!" Brightly colored rivets are being churned out by machines in the production department of a cardboard box factory in Shengang Township, Taichung County. These colorful plastic rivets, newly encased in iron rivet heads and no larger than 2.55 centimeters, are seen as the "new hardware" capable of driving traditional cardboard box factories towards the creative furniture industry.

These colorful little rivets, patented in 2000, are referred to as "DIY Rivets" by their inventor, Benson Chen, who has been in the cardboard box industry for over 30 years.

Late Bloomer Awarded at Nuremberg Inventors' Fair

Benson Chen applied rivets in the composite assembly of cardboard boxes. Upon its debut, this creation won the National Invention Excellence Award in 2001. It later ventured to Germany, winning silver and bronze medals at the Nuremberg World Invention Exhibition in 2002 and 2004.

Chen's DIY Rivet concept, inspired by the stacking flexibility of LEGO toys, involved combining different materials, transforming cumbersome furniture into easily assembled pieces like LEGO blocks. Despite his many accolades, Chen was a latecomer to the furniture industry.

Before inventing DIY Rivets in 2000, Chen was the owner of Shili Paper Box Factory for thirty years, an outsider in the furniture industry. At 55, he now holds the title of General Manager at Shili Hsing Company, aiming to revolutionize traditional furniture concepts with DIY Rivets and cardboard.

Traditional Industry Unrest with Steady Profits

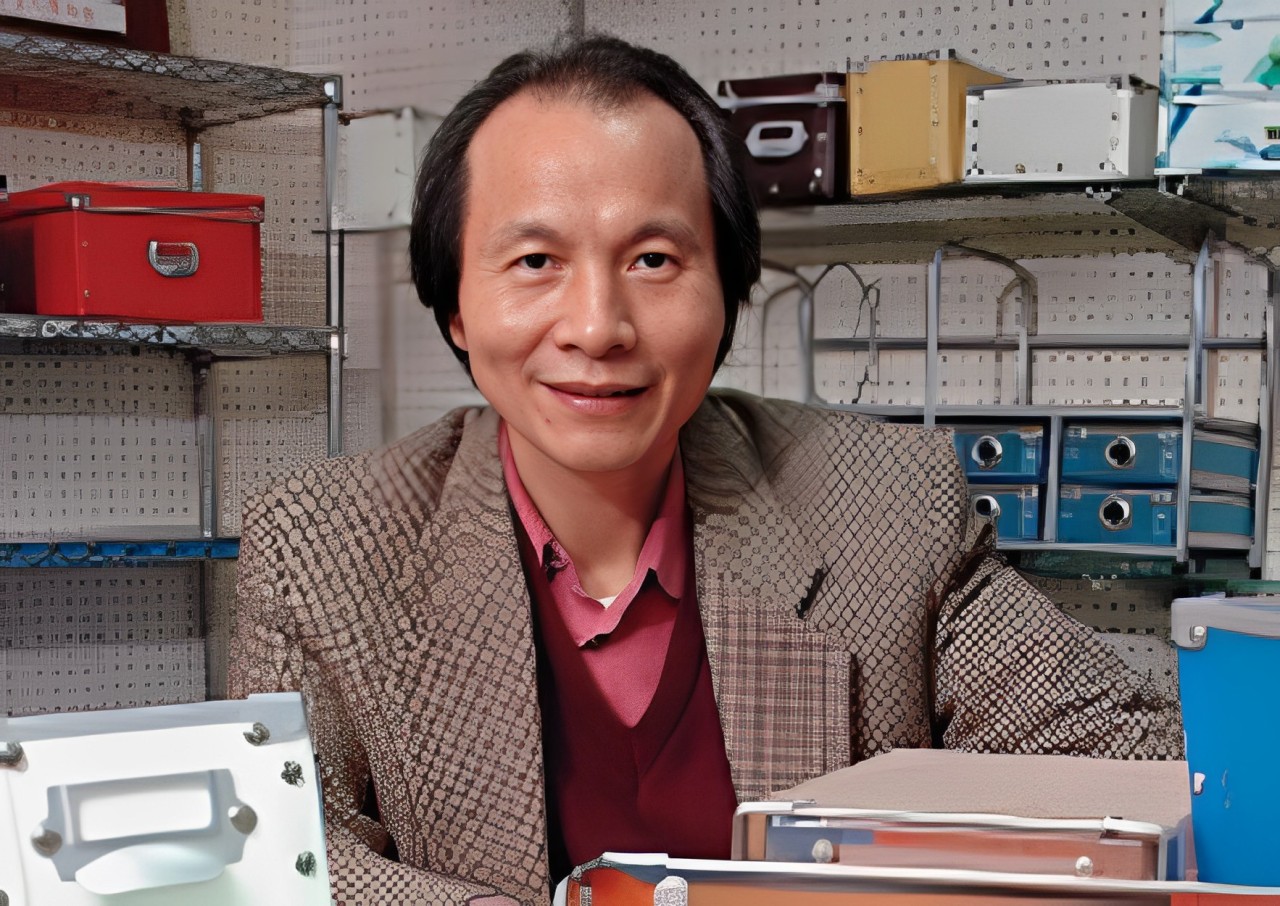

Chen, often seen in plaid suits with a simple smile, fits the traditional image of a cardboard factory owner. Few know that he is an international businessman who types English emails faster than Chinese ones and directly negotiates with clients from Europe, the US, and Japan.

In the booming 1970s Taiwanese export industry, Fengyuan City, Taichung County, faced a high demand for cardboard boxes. Chen, without much thought, established a cardboard factory with a capital of NT$200,000, recouping the capital within six months.

However, brimming with ideas, Chen was not content with steady profits.

American Experience: Transforming the Cardboard Box Factory

In 1984, aiming to expand his business, Chen ventured alone to the US. Although he didn’t make big money there, his cardboard business back home kept him afloat.

During his three years in the US, Chen frequently visited Kmart, noticing the growing dominance of "Made in China" products. Realizing the cardboard industry would eventually shift to China due to lower costs, he began thinking about breaking through and transforming the cardboard factory towards "paper commoditization."

Inventing Rivets: Finding the Core for Transformation

The road to transformation was not easy.

Back in Taiwan in 1990, Chen invented waterproof advertising cardboard, earning his first patent. This waterproof cardboard brought him NT$600,000 in monthly net profits, despite later facing strict environmental regulations that curtailed its success.

It wasn't until the emergence of DIY Rivets that Chen's concept of "paper commoditization" found its core.

In 1999, during a visit to IKEA, Chen noticed a piece of furniture using plastic screws as fasteners. Intrigued, he started thinking about making furniture fasteners more lightweight and convenient, often jumping up at night to draw designs and discuss them with friends in plastic and metal industries.

In 1999, the first rivet was born. Chen divided the rivet into two parts, which could be fastened with just two fingers and couldn't be pulled apart by hand but could be easily disassembled with a simple tool.

After enhancing the rivet's strength, different-sized rivets could securely fasten both soft and hard materials. Soft materials like cardboard and leather could be fastened together with rivets, and similarly, soft materials could be locked onto hard materials like steel frames and wood.

From Rivets to Paper Furniture: Exploring Business Opportunities

If market demand couldn't be grasped, the easy-to-assemble DIY Rivets would be just another novelty.

"The more innovative, the higher the risk," said Liang Youzhao, Chairman of the Industrial Design Association and guest professor at Chang Gung University’s Industrial Design Department. True innovation involves mastering the triad of "market," "technology," and "manufacturing," without which innovation and profit remain separate.

In 2003, Chen joined the Taipei Tech Innovation Incubation Center, guided by Liang to focus on a few key products. The standout, popular in the US and Japan markets, was the "LEGO-style furniture."

Commercial Success: LEGO Furniture's Foreign Market Popularity

Confident in the "blue ocean" of creative furniture, Chen's LEGO-style furniture, using DIY Rivets, could be stacked like LEGO blocks. The main materials were cardboard and PP corrugated board, with structures supported by hard materials like steel.

This type of lightweight box, assembled with DIY Rivets, could be combined and stacked into wardrobes, shelves, and shoe cabinets, weighing less than a third of conventional furniture.

Chen's furniture series, mainly for the export market, sells to students and young professionals in Europe, the US, and Japan. Recently, his ACEKEA brand has been placed on auction websites, and he is developing an online pricing software to calculate combinations and prices for LEGO furniture based on user input.

With over twenty patents, Chen plans for this software to be his next patent.

Next Step: Own Brand

DIY Rivets changed Chen and his cardboard factory's destiny.

Despite the decline of Taiwanese cardboard factories, Shili Carton Factory, driven by Acerly's subsidiaries, remains one of the few planning expansion without moving to China.

Over the past five years, LEGO-style furniture derived from DIY Rivets accounted for 30% of Shili's total revenue, growing 5% annually, with total revenue reaching NT$70 million to NT$100 million per year.

Yet, Chen's path through the "Eighteen Arhat Array" is only halfway through. He hopes to promote DIY Rivets wherever fasteners are needed, aiming for a proprietary brand store.

---

This article is from the April 2006 edition of "Embracing a Trillion Business Opportunities: Boredom is Gold."